What to Do If Your Pilot Light Keeps Going Out

A pilot light that repeatedly goes out can be a frustrating and concerning issue for homeowners. Your water heater, furnace, or gas fireplace relies on a steady pilot light to function properly. If you’re experiencing this problem, it’s important to identify the cause and address it promptly to prevent further inconvenience or potential safety risks. In this blog, we’ll explore common reasons why your pilot light may be going out and what you can do to fix it.

Common Causes of a Pilot Light Going Out

- Dirty or Clogged Pilot Orifice Over time, dust, dirt, and debris can build up in the pilot orifice, restricting the gas flow. This can cause a weak or unstable flame that is more likely to go out. If this issue is not addressed, it can lead to inefficient heating and higher energy costs.

- Faulty Thermocouple The thermocouple is a safety device that detects whether the pilot light is on. If it senses that the flame is out, it shuts off the gas supply to prevent leaks. A malfunctioning thermocouple may incorrectly shut off the gas even when the pilot light is still lit. This could be due to a worn-out component, corrosion, or a misalignment issue.

- Drafts or Airflow Issues A strong draft or sudden gust of air can blow out the pilot light. Poor ventilation, an open window, or a nearby HVAC system could be creating airflow problems. Additionally, a faulty or loose vent cover can allow external air to disrupt the flame.

- Gas Supply Problems If the gas supply is interrupted or insufficient, the pilot light may struggle to stay lit. Low gas pressure, a closed or partially closed gas valve, or an issue with the gas line could be responsible. Sometimes, regional gas supply fluctuations can also contribute to this problem.

- Malfunctioning Gas Control Valve The gas control valve regulates the flow of gas to the pilot light. If this component is damaged or defective, it may not deliver enough gas to sustain the flame. Over time, wear and tear or debris buildup inside the valve can cause it to malfunction, requiring professional attention.

- Moisture Buildup In humid conditions, moisture buildup can interfere with the pilot light’s ability to stay lit. If condensation forms inside the appliance, it can extinguish the flame, particularly in water heaters located in damp basements or garages.

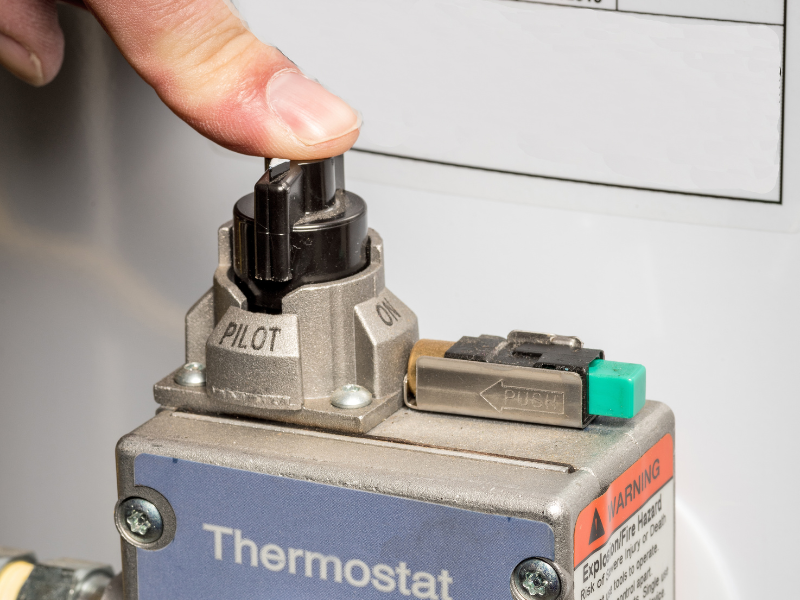

Steps to Fix a Pilot Light That Keeps Going Out

If your pilot light keeps going out, follow these troubleshooting steps:

- Turn Off the Gas Supply Before performing any maintenance, turn off the gas supply to your appliance. Locate the gas valve and switch it to the “off” position to prevent gas leaks.

- Clean the Pilot Orifice Use a thin wire, needle, or compressed air to carefully clear out any debris from the pilot orifice. This will help ensure proper gas flow and a stable flame. Regular cleaning can prevent future clogs and maintain efficiency.

- Inspect and Replace the Thermocouple If your thermocouple is faulty or misaligned, it may need to be cleaned, adjusted, or replaced. Make sure the tip of the thermocouple is properly positioned in the pilot flame. If replacing it, ensure you purchase the correct model for your specific appliance.

- Check for Drafts Identify any sources of drafts near the appliance and eliminate them. Close nearby windows and doors, and ensure that the pilot flame is protected from airflow disruptions. If necessary, install a draft shield or move the appliance to a less draft-prone area.

- Examine the Gas Supply Verify that the gas valve is fully open and that there are no interruptions in your gas supply. If you suspect a gas pressure issue, contact your utility provider or a professional plumber to assess and resolve the issue.

- Test the Gas Control Valve If all else fails, the gas control valve may need to be inspected or replaced. This is a job best handled by a licensed plumber or HVAC technician, as improper installation can pose safety risks.

- Address Moisture Issues If moisture buildup is extinguishing your pilot light, try running a dehumidifier in the area where the appliance is located. You can also insulate gas lines and the appliance itself to reduce condensation.

When to Call a Professional

While some pilot light issues can be resolved with basic troubleshooting, certain problems require professional expertise. If you notice any of the following, it’s best to call a licensed plumber:

- A persistent gas smell, which could indicate a leak

- Difficulty relighting the pilot light even after cleaning and maintenance

- The flame is weak, flickering, or has an unusual color (e.g., yellow instead of blue)

- Repeated pilot light failures despite troubleshooting efforts

- Visible corrosion or damage to components such as the thermocouple or gas valve

At Rocket Plumbing, our experienced technicians can diagnose and repair pilot light issues quickly and safely. We have the tools and expertise to ensure your appliance is functioning properly and efficiently. If you’re dealing with a stubborn pilot light problem, don’t hesitate to contact us for professional assistance.

Preventative Maintenance Tips

To avoid future pilot light issues, consider the following maintenance tips:

- Schedule annual inspections: Have a professional inspect and service your gas appliances at least once a year.

- Keep the area clean: Dust and debris can accumulate around gas appliances, affecting airflow and operation.

- Check gas connections regularly: Ensure gas valves and lines are in good condition to prevent leaks.

- Monitor flame color: A healthy pilot light flame should be blue. If it turns yellow or orange, it may indicate a problem with gas combustion.

Final Thoughts

A pilot light that won’t stay lit can be a nuisance, but with the right troubleshooting steps, you can often resolve the issue yourself. However, for persistent or complex problems, it’s best to seek professional help. Keeping your gas appliances in good working condition ensures efficiency, safety, and peace of mind.

Need help with your pilot light? Contact Rocket Plumbing today for expert plumbing solutions! Our team is here to assist you with all your plumbing and gas appliance needs, ensuring a safe and comfortable home environment.